High Efficiency Miller Cycle Gas Engine

Index | |

SR No. | Content |

1 | INTRODUCTION |

2 | Elementary Technology |

2.1 Application of Miller cycle 2.2 Setting of expansion ratio/compression ratio 2.3 Improvement in combustion performance 2.4 Improvement in turbocharger performance | |

3 | DEVELOPMENT FOR COMMERCIALIZATION |

3.1 Application of air-fuel ratio electronic-control system 3.2 Adoption of heavy-duty iridium spark plug 3.3 Setting the ignition timing 3.4 Endurance test and analytical check evaluation | |

4 | CONCLUSION |

5 | REFERENCES |

1. INTRODUCTION

The output of gas engines for cogeneration mainly ranges from 100 to 1 000 kW. The present gas engines are broadly classified in two types: lean-burn system (1) and stoichiometric air-fuel ratio combustion system, with the lower output engines using the stoichiometric Air-fuel ratio combustion system while the medium and large size engines adopting the lean-burn system. The lean-burn system generally features in high generating efficiency and low NOx emission in addition to the excellent endurance of the low-temperature combustion flame.

Mitsubishi Heavy Industries, Ltd. (MHI) and Osaka Gas Co., Ltd. have jointly applied the Miller cycle to a lean-burn gas engine to develop the world’s first gas engine in this class with the generating efficiency standing at 40%. With the 280 kW engine released commercially in April 2000 after having cleared the endurance test over 4 000 hours, this paper describes the main technologies and performance specifications for this engine as well as for the series

of engines planned in the future.

2. ELEMENTARY TECHNOLOGY

This section deals with the applied elementary technologies and developments

2.1. Application of Miller cycle

The theoretical cycle efficiency in a conventional cycle internal combustion engine with nearly equivalent compression ratio and expansion ratio is expressed by equation (1).

Theory=1-1 - (1) where: engine compression ratio ( expansion ratio)

: Adiabatic index of working fluid

This indicates that it is necessary to increase the compression ratio in order to improve the theoretical cycle efficiency. In the case of a natural gas engine, however, the increase of the compression ratio raises the cylinder gas temperature. This causes knocking due to the auto-ignition of unburnt gas before the flame reaches the end gas area, causing the temperature and pressure inside the cylinder to rise sharply until the engine gets damaged (broken). In order to prevent this, it is necessary to delay the ignition timing, but delaying the ignition timing leads to the reduction of the degree of constant volume of combustion (the index including the degree of efficiency reduction against the constant volume combustion cycle), nullifying the effect of high theoretical cycle efficiency. Miller cycle was presented by Miller (2) as a cycle to solve the aforesaid problems. In the case of a conventional reciprocating internal combustion engine the inlet valve close timing and the exhaust valve open timing are adjacent to the bottom dead center (BDC), and the compression ratio is nearly equivalent to the expansion ratio. In the Miller Cycle, the effective close timing of the inlet valve is slightly shifted forward or backward from the bottom dead center to decrease only the effective compression ratio, making expansion ratio > compression ratio. In the case of an internal combustion engine with expansion ratio > compression ratio, the compression ratio in equation (1) can safely be used as the expansion ratio. In other words, by applying the Miller cycle, the compression ratio can be kept to a level that prevents knocking, while keeping the expansion ratio at a high level to ensure high efficiency.

Quite a few researches and developments have so far been made on the application of Miller cycle, with a few of them already commercialized (3)-(5). In each case, however, the stoichiometric air-fuel ratio combustion system engine with low thermal efficiency has basically been used, so that the Miller cycle has so far not been used for commercialization at the thermal efficiency exceeding 40% level. In our development program, we applied Miller cycle basically for lean-burn gas engines with pre-chamber system having a high thermal efficiency of 37%, aiming at a thermal efficiency of 42.2% (at a generating efficiency of 40%). We set up a target in our development program using simulation, etc. in order to raise the conventional engine thermal efficiency from 37% to 42.2%. The development program proceeded putting the target to getting the thermal efficiency improved by 3% or over by improving the theoretical cycle efficiency through the set expansion ratio/compression ratio, and the remaining 2.0% by improving the degree of constant volume of combustion and combustion efficiency and by reducing the heat loss and pumping loss

2.2 Setting of expansion ratio/compression ratio

First of all we studied the expansion ratio and compression ratio through performance calculation (6), paying attention to the pulsation inside the inlet and exhaust pipes, and grasped the appropriate values. Fig. 1 shows the relation between expansion ratio and estimated thermal efficiency, indicating obviously that the engine thermal efficiency of 40% can be achieved by setting the expansion ratio (compression ratio based on bottom dead center) to 15. Thus, the expansion ratio based on the calculation result was set to 15. Further, the inlet valve close timing was experimentally set. Fig. 2 shows the relation between the actually measured effective compression ratio (estimated from the relation between boost pressure and compression pressure) using a six-cylinder test engine shown in Table 1 and the thermal efficiency at maximum advance ignition timing and inlet manifold pressure. Excessively high effective compression ratio causes knocking calling for delay in ignition timing, which causes the thermal efficiency to get reduced.

On the other hand, excessively low effective compression ratio causes the pressure ratio required for the turbocharger to get excessively high. Thus, from the test result in Fig. 2 we selected the inlet valve close timing that provides the effective compression ratio of 11.

2.3. Improvement in combustion performance

In the case of a Miller cycle gas engine the combustion chamber volume at compression top dead center (TDC) is reduced because of the high expansion ratio. This causes the combustion efficiency to get reduced, nullifying the effect of high expansion ratio, and inversely reducing the efficiency. The major problem in this development program was tonsure combustion efficiency equivalent to or higher than that of a conventional gas engine at a smaller volumetric space. Hence, we developed the main chamber shape using a single cylinder test engine shown in Table 1, the optimization of inlet air swirl ratio, and pre-chamber specification.

(1) Main (combustion) chamber shape

As for the shape of the main (combustion) chamber, two types were tested. One was a high turbulence type, aiming at increasing combustion speed through enhanced turbulence speed inside the combustion chamber, and the other was a low unburnt type, aiming at reducing the unburnt gas by reducing the top clearance section. The test results are shown in Fig. 3.It is obvious from the figure that the low unburnt type combustion chamber is less likely to cause knocking, and therefore enables to advance the ignition timing, causing the degree of combustion constant volume g1 to improve, the exhaust total hydro-carbon (THC) concentration improved.

(2) Swirl ratio

Next, investigation was made on the effect of swirl ratio. The swirl ratio refers to an evaluation level indicating the strength of circling flow inside the cylinder following the air intake. Fig. 4 shows the changes in heat release rate and engine performance when the swirl ratio is changed. As shown in Fig. 4(a), a high swirl ratio causes the maximum heat release rate to increase, and in the meantime, the heat release period to get shortened. This causes knocking to occur easily. Moreover, a high swirl ratio increases the heat transfer rate from the high temperature burnt gas to cylinder liner, causing the heat loss to get increased. Accordingly, as shown in Fig. 4(b), the thermal efficiency does not improve at high swirl (rate) in spite of the low exhaust THC (Total Hydro- Carbon) concentration. From the test result we decided to set the swirl ratio to a lower level.

(3) Pre-chamber

In the case of a gas engine with pre-chamber, the main chamber combustion has been found to be largely affected by the spark ignition inside the prechamber and the motion of the torch flame from the pre-chamber. in other words, the inner shape of the pre-chamber and the nozzle specification largely influences the combustion efficiency and heat release period. Consequently, the optimum pre-chamber specification (volume and nozzle type) was developed making use of the three-dimensional cfd and optical test

2.4. Improvement in turbocharger performance

The inlet valve opening volume in a Miller cycle gas engine gets small because the piston is quite above the bottom dead center when the inlet valve is closed in order to reduce the effective compression ratio, causing the volumetric efficiency to get drastically reduced.

Accordingly, higher boost pressure is required to maintain the same output, i.e., a turbocharger with low flow rate and high-pressure ratio is needed. However, among the turbochargers of mass production, there was no turbocharger like a Miller cycle engine with low flow rate and high-pressure ratio in addition to high efficiency. A turbocharger with low efficiency causes the exhaust pressure to rise and thereby the pump loss to increase, no matter how high the engine cylinder cycle efficiency is. The thermal efficiency consequently does not improve. In other words, a high efficiency supercharging system is indispensable to a Miller cycle engine.

We, therefore, developed a turbocharger optimized for Miller cycle. This was done optimizing the turbine and compressor component elements to obtain higher efficiency. A new type 3-dimensional blade with inner and exit flow loss reduced was adopted for the turbine while the nozzle blade shape and scroll shape were optimized to obtain high efficiency. In the case of compressor, a new type 3-dimensional impeller with the secondary flow loss reduced inside the impeller was applied and the scroll shape was improved to obtain high efficiency. As a result, we could develop the world's first turbocharger in this class with the efficiency standing at 62%.

By combining the aforesaid elementary technologies we could successfully realize an engine thermal efficiency 42.2% and generating efficiency 40%.

3. DEVELOPMENT FOR COMMERCIALIZATION

We applied the newly developed elementary technologies to a six-cylinder engine in order to execute the development program for commercialization

3.1 Application of air-fuel ratio electronic-control system

In order to control the air-fuel ratio to an optimum range, it is necessary to control the flow rate of fuel gas and air. In the case of the newly developed Miller cycle gas engine, the air-fuel ratio electronic-control system was applied. The system calculates the required fuel gas feed rate on the basis of the temperature and pressure in the inlet manifold and the engine speed, and controls the gas feed rate using the solenoid valve. This enables optimum control at air-fuel ratio irrespective of the changes in external conditions, ensuring constant maintenance of high engine reliability and performance

3.2 Adoption of heavy-duty iridium spark plug

Compared with a conventional gas engine, the Miller cycle gas engine has higher cylinder pressure and higher ignition request voltage of the ignition plug, so that the conventional platinum spark plug had its electrode wear out shortly, and it was difficult to maintain the plug life over 2000 hours. Hence, we developed a new iridium spark plug with high endurance for the newly developed engine

3.3 Setting the ignition timing

In order to set the ignition timing, we used retard 4 crank angle from the knock limit to ensure the reliability of the engine

3.4 Endurance test and analytical check evaluation

An endurance test was conducted prior to the commercialization. Fig. 5 shows the transition of engine thermal efficiency, indicating the engine thermal efficiency standing at 42-43%. The engine was further put to overhaul after 4 000 hours to confirm that the piston, piston ring, exhaust and inlet valves, prechamber and others had the wear levels equivalent to those of a conventional gas engine and had no problems whatsoever.

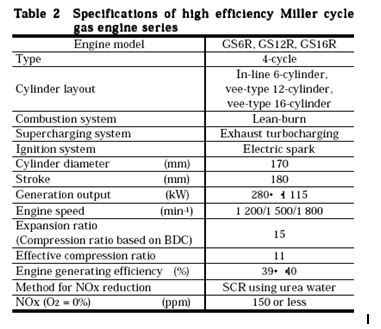

The specifications of the high-efficiency Miller cycle gas engine employing the newly developed technologies are given in Table 2. As shown in Table 2, the exhaust NOx (emission) has been reduced to 150 ppm (O2= 0% conversion) or under by applying a simplified deNOx system using urea water. The 280 kW, 1 200-min-1, in-line 6-cylinder engine was commercially released in April 2000. We are further planning to put the other engines successively on sale. Fig. 6 shows a comparison of various size gas engines in terms of thermal efficiency.

4. CONCLUSION

The technologies given below were applied to the development of a high-efficiency gas engine.

(1) Miller cycle with expansion ratio 15 and compression ratio 11

(2) Combustion system to restrain knocking

· Low inlet air swirl

· Low unburnt type combustion chamber shape

· Pre-chamber nozzle and volumetric specification optimization

(3) High-efficiency turbocharger

Through the combination of these technologies the engine thermal efficiency of 42.2% (the generating efficiency of 40%) could be attained. As for the generating efficiency, it was improved by 5% of the conventional lean-burn gas engine, reaching the 40% level, the top in the world. The engines with output 280-1 115 kW are planned to put successively to commercialization, with the 280 kW, engine already released commercially in April 2000.

5.REFERENCES

1. www.google.com

2. www.mistubushimotors.com

3. www.howstuffworks.com

4.www.edufive.com/seminartopics.html

No comments:

Post a Comment